TPM series switchgear are a group of medium voltage ring type switchgear (RMU - Ring Main Unit), in SF6 gas insulation for use indoors. They are designed for supply and secondary distribution of electricity in radial and ring urban grids, in industry and in all facilities where compact switchgears with high technical parameters are very desirable. The switchgears are manufactured and tested based on the following standards. Type testing performed by independent accredited certification bodies. The test results are confirmed by appropriate certifications and test reports.

Characteristics

Characteristics

- miniature switchgear dimensions while maintaining high technical parameters,

- very high safety level, including arc protection - confirmed by appropriate certificates,

- possibility to configure the switchgear from a range of different purpose bays: feeder, transformer, circuit breaker, metering, cable bays,

- the possibility of configuring the switchgear with the use of a wide range of bays: feeder, transformer, circuit-breaker, bus coupler, metering,

- possibility of easily expanding the switchgear with additional assemblies (which should be taken into account when placing the order) each assembly may be manufactured as expandable,

- the possibility of adapting the switchgear to work with remote control and metering systems, e.g. to work in Smart Grid networks,

- fast earthing switch, which earths the fuse link on both sides in the transformer bay,

- the main SF6 gas tank is made of stainless, acid-resistant steel, with welded connections, which ensure environmental and 6 personal safety, and remain sealed over the entire period of switchgear operation,

- the manufacturer is able to recycle the waste switchgear and safely remove the SF6 gas from their tanks.

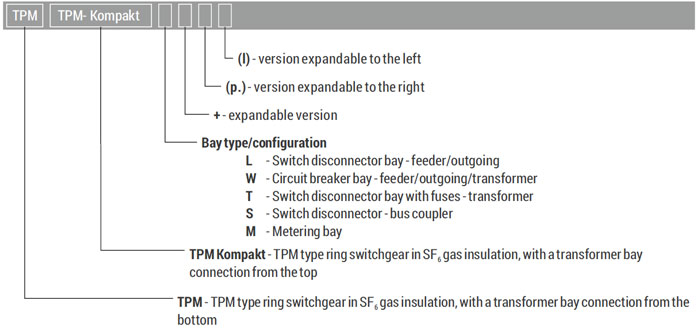

Possible markings/naming scheme

Safety

- robust construction of TPM type switchgear ensures high reliability,

- the tank is constructed of stainless, acid-resistant steel, ensuring resistance to environmental conditions,

- use of shielded terminations guarantees safety, e.g. during servicing operations with the front panel removed and live supply cables,

- gas pressure indicator - pressure meter which shows the correct pressure of insulating gas inside the tank,

- resistance to internal arc of 20 kA as a standard and 22 kA in custom design,

- pressure increase caused by internal arcing is eliminated by opening the safety valve installed in the lower part of the switchgear's tank. The gases are discharged to the cable duct, eliminating the hazard to personnel,

- each switchgear unit is equipped with voltage indicators, which enable the personnel to make sure that the insulating bushing terminals are not live,

- legible system display which improves intuitiveness of operation and facilitates reading the state of devices,

- a set of mechanical interlocks enables opening the front panels of the cable compartment only after the earthing switch is closed,

- a set of mechanical interlocks between the devices, which prevents performing incorrect switching operations,

- optional use of electromagnetic interlocks, which prevent the closing of the earthing switch with live supply cables,

- a set of auxiliary contacts with device state output, guaranteeing safety of remote operation,

- the use of pressure control at all times for the motor drive option guarantees safety of remote operation.

Basic technical data

Compliance with standards:

The TPM type switchgear meets the requirements of the following standards:

- PN-EN 62271-1 - „High-voltage switchgear and controlgear - Part 1: Common specifications”,

- PN-EN 62271-200 - „High-voltage switchgear and controlgear - Part 200: AC metal-enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV”,

- PN-EN 62271-100 - „High-voltage switchgear and controlgear - Part 100: High-voltage alternating-current circuit-breakers”,

- PN-EN 62271-102 - „High-voltage switchgear and controlgear - Part 102: High-voltage alternating current disconnectors and earthing switches”,

- PN-EN 62271-103 - „High-voltage switchgear and controlgear - Part 103: Switches for rated voltages above 1 kV up to and including 52 kV”,

- PN-EN 62271-105 - „High-voltage switchgear and controlgear - Part 105: Alternating current switch-fuse combinations”.

The switchgear is certified by the Electrotechnical Institute.

| TPM switchgear rated parameters | ||

| MV rated voltage | Ur | 25 kV |

| Rated frequency - number of phases | Fr | 50 / 60 Hz / 3 |

| Rated network frequency withstand voltage | Ud | 50 kV / 60 kV |

| Withstand lightning surge voltage (1.2/50 μs) | Up | 125 kV / 145 kV |

| Primary busbars continuous rated current | Ir | 630A |

| Rated short-time withstand primary circuits current | Ik | 16 kA (3s) / 20 kA (1s) / 25 kA (3s) *1) |

| Rated peak withstand primary circuits current | Ip | 40 kA / 50 kA / 63 kA *1) |

| Resistance to internal arc effects | IA | 20 kA (1s) / 22 kA (1s) *1) |

| IAC class | AFLR | |

| IP protection rating | IP4X (IP54 option) | |

| Mechanical impact resistance | IK10 | |

| 1) Custom design | ||

| Environmental service conditions: | |

| Ambient temperature | |

|

- peak short-time

|

+ 40°C

|

|

- highest day average

|

+ 35°C

|

|

- minimum

|

|

|

- without secondary circuits

|

- 25°C

|

|

- with secondary circuits

|

- 5°C / - 15°C / - 25°C 2)

|

| Relative humidity of air | |

|

- highest day average

|

95%

|

|

- highest month average

|

90%

|

| Vibrations | vibrations caused by external factors or earthquakes negligible |

| Internal Protection | |

|

- device compartment, stainless steel SF6 tank

|

IP 67 |

|

- drive mechanism and connections compartment

|

IP 4X |

| Soiling conditions | |

|

- significant soiling with salt, vapour, dust, smoke, flammable gases

|

NONE |

|

- corrosive

|

NONE |

|

- icing, frosting and dewing

|

NONE |

| 1) Unless the manufacturer of instrumentation & control and protection devices has specified otherwise. | |

Notice:

Rated currents of the fuse links to protect primary transformer circuits (recommended by leading manufacturers), with rated voltage 6 kV, 10 kV, 15 kV and 20 kV, should be selected in accordance with IEC 282-1, DIN 43625 thermal protection.

Field equipment

L - line feeder equipment

| Parameters | |

| Ur | = 25 kV |

| Fr | = 50/60 Hz |

| Ud | = 50/60 kV |

| Up | = 125/145 kV |

| Ir | = 630 A |

| Ik | = do 20 kA |

| Ip | = do 50 kA |

| IA | = do 22 kA |

| switch disconnector class M2, E3 | |

| earthing switch class M0, E2 | |

| Electrical data of line functional unit (L) | ||

| Continuous rated current | Ir | 630 A |

| Rated short-circuit making current | Ima | 50 kA |

| Rated low inductance circuit breaking current | Iload | 630 A |

| Rated ring network circuit breaking current | Iloop | 630 A |

| Rated buried cable charging breaking current | Iicc2 | 60 A |

| Rated overhead line charging breaking current | Iicc1 | 20 A |

| Rated earth fault breaking current | Ief1 | 180 A |

| Rated buried cable and overhead line charging breaking current in earth fault conditions | Ief2 | 104 A |

| Switch disconnector class | M2, E3 | |

| Earthing switch class | M0, E2 | |

- meets the requirements of the PN-EN 62271-103 Switches for rated voltages above 1 kV up to and including 52 kV standard,

- the L unit as a single module with option of expanding, in almost any configuration up to four units in a common tank,

- disconnector-earthing switch unit, the construction of which is based on common moving contacts and separated fixed contacts of the earthing switch and switch disconnector,

- switch disconnector with a switching operations arc quenching system,

- manual double spring drive which ensures intuitive and easy operation and snap-action closing and opening of the switching devices,

- system display representing the state of devices and entire primary circuits,

- type C insulating bushings with M16 thread, equipped with capacitive voltage dividers intended for operation with voltage indicators in the LRM system and to operate with electromagnetic interlocks,

- cable voltage indicator in the LRM system,

- pressure meter - gas pressure indicator with a scale with two zones, indicating the rated absolute pressure of the SF6 gas - 125 kPa (0.125 MPa) at a temperature of 20°C (one per one 6 tank),

- a system of mechanical interlocks between the devices and front panels of the cable compartment preventing incorrect switching operations - removing the front panel only after closing the earthing switch,

- safety valve (one per one tank), which is opened by pressure increase caused by arcing inside the tank, directing the gases downwards, to the cable duct, eliminating the hazard to personnel,

- cable clamps.

- 24 V DC motor drive (other supply voltage on request), possibility of easy expansion at the facility,

- pressure control - for operating with motor drive, telemetry,

- SEM SC 11 field controller plus local control panel, Modbus communication or binary communication

- auxiliary contacts as representation of state of devices for telemetry systems,

- voltage sensors - low power transformers,

- current transformers, Rogowski coils,

- earth fault transformers,

- short-circuit current indicators,

- auxiliary circuits cubicle/operation with telemetry,

- “ON”, “OFF” signalling in the form of signalling lamps,

- anti-condensation heaters,

- possibility of expanding on the left and right side,

- key interlock of the switch disconnector or earthing switch socket,

- electromagnetic interlock of the earthing switch socket,

- overvoltage limiters.

T - tansformer feeder equipment

| Parameters | |

| Ur | = 25 kV |

| Fr | = 50/60 Hz |

| Ud | = 50/60 kV |

| Up | = 125/145 kV |

| Ir | = 250 A (125 A fuse link) |

| Ik | = 20 kA (1s) |

| Ip | = 50 kA |

| IA | = do 22 kA |

| Itransf | = 720 A |

| switch disconnector class M2, E3 | |

| Electrical data of the fused transformer functional unit (T) | |||

| Continuous rated current | Ir | 250 A | |

| Maximum thermally protected fuse link current | 125 A | ||

| Through-current | Itransfer | 720 A | |

| Switch disconnector electrical class | M2, E3 | ||

| Maximum transformer power | 6 kV | 800 kVA | |

| 10 kV | 1000 kVA | ||

| 15 kV | 1600 kVA | ||

| 20 kV | 2000 kVA | ||

- meets the requirements of the PN-EN 62271-105 Alternating current switch-fuse combinations standard

- the T unit as a single module with option of expanding, in almost any configuration up to four units in a common tank,

- disconnector-earthing switch unit, the construction of which is based on common moving contacts and separated fixed contacts of the earthing switch and switch disconnector,

- lower earthing switch, ensuring earthing on both sides of the fuse links,

- switch disconnector with a switching operations arc quenching system,

- manual double spring drive which ensures intuitive and easy operation and snap-action closing and opening of the switching devices,

- system display representing the state of devices and entire primary circuits,

- stored energy release mechanism function, which allows the switch disconnector contacts to be opened when MV fuse links with thermal protection (striker) or a tripping coil is used,

- blown fuse link indicator,

- type A insulating bushings with plug-in socket, equipped with capacitive voltage dividers intended for operation with voltage indicators in the LRM system and to operate with electromagnetic interlocks,

- cable voltage indicator in the LRM system,

- a system of mechanical interlocks between the devices and front panels of the cable connection compartment preventing incorrect switching operations - removing the front panel only after the earthing switch is closed,

- safety valve (one per one tank), which is opened by pressure increase caused by arcing inside the tank, directing the gases downwards, to the cable duct,

- cable clamps.

- 24 V DC motor drive (other supply voltage on request), possibility of easy expansion at the site,

- pressure control - for operating with motor drive, telemetry,

- SEM SC 11 field controller plus local control panel, binary or Modbus communication,

- auxiliary contacts as representation of state of devices for telemetry systems,

- fuse links with integrated temperature limiter (thermal trip), acc. to the IEC 60282-1, DIN 43625 standard, e.g. by SIBA

- voltage sensors - low power transformers,

- current transformers, Rogowski coils,

- “ON”, “OFF” signalling in the form of signalling lamps,

- anti-condensation heaters,

- possibility of expanding on both sides,

- key interlock of the disconnector or earthing switch socket,

- electromagnetic interlock of the earthing switch socket, option dedicated for renewable energy system,

- shunt trip - DWN 24 V DC coil, 230V AC/DC (other voltages on request).

W - circuit breaker feeder

| Parameters | |

| Ur | = 25 kV |

| Fr | = 50/60 Hz |

| Ud | = 50/60 kV |

| Up | = 125/145 kV |

| Ir | = 630 A |

| Ik | = do 20 kA (1s) |

| Isc | = do 50 kA |

| Icc1 | = 10 A |

| Icc2 | = 31,5 A |

| circuit braker class M2, E2 | |

| operating sequence duty cycle (O-0, 3s-CO-3min-CO) | |

| Electrical data of circuit breaker feeder (W) | ||

| Continuous rated current | Ir | 630 A |

| Short-circuit making current | Ima | 40 kA / 50 kA / 52,5 kA *1) |

| Short-circuit breaking current | Isc | 16 kA / 20 kA / 21 kA *1) |

| Rated low inductance circuit breaking current | 630 A | |

| Cable line current with no load - Icc1 / Icc2 | Icc1 / Icc2 | 10 A / 31,5 A |

| Circuit breaker class | M2, E2 | |

| Operating sequence duty cycle | 0-0, 3s-CO-3min-CO | |

Custom design:

1) For 12 kV voltage.

- meets the requirements of the PN-EN 62271-100 Alternating current circuit-breakers standard,

- meets the requirements of the PN-EN 62271-102 Alternating current disconnectors and earthing switches standard,

- the W bay as a single module with option of expanding, in almost any configuration up to four bays in a common tank,

- circuit breaker unit, the construction of which is based on the use of vacuum chambers with a breaking current of 16 kA or 20 kA, enclosed in an SF6 gas filled tank,

- disconnector-earthing switch unit, the construction of which is based on common moving contacts and separated fixed contacts of the earthing switch and disconnector. The function of the disconnector is to ensure a safe gap in the circuit,

- manual spring drive of the circuit breaker, which ensures intuitive and easy operation and snapaction closing and opening of the switching devices, the drive has a charging system which allows a rapid breaker on-off cycle,

- manual spring-less drive of the disconnector and earthing switch, which ensures intuitive and easy operation of the switching devices,

- system display representing the state of devices and entire primary circuits,

- circuit breaker charging indication,

- independent protection, preferably AZZ-4 (by ITR) or WIC 1 (by Woodward) with dedicated current transformers,

- type C insulating bushings with M16 thread, equipped with capacitive voltage dividers intended for operation with voltage indicators in the LRM system and to operate with electromagnetic interlocks,

- cable voltage indicator in the LRM system,

- pressure meter - gas density indicator with a scale with two zones, indicating the rated absolute pressure of the SF6 gas - 125 kPa (0.125 MPa) at a temperature of 20°C (one per one tank),

- a system of mechanical interlocks between the devices and front panels of the cable compartment preventing incorrect switching operations - removing the front panel only after closing the earthing switch,

- safety valve (one per one tank), which is opened by pressure increase caused by arcing inside the tank, directing the gases downwards, to the cable duct, eliminating the hazard to personnel,

- cable voltage indicator,

- cable clamps.

- 24V DC motor drive for the circuit breaker and for the disconnector and earthing switch (other supply voltage on request),

- pressure control - for operating with motor drive, telemetry,

- auxiliary contacts as representation of state of devices for telemetry systems,

- protections other than preferred independent, unit controllers, ATS automation,

- voltage sensors - low power transformers,

- current transformers, Rogowski coils,

- earth fault transformers,

- auxiliary circuits cubicle/operation with telemetry,

- “ON”, “OFF” signalling in the form of signalling lamps,

- anti-condensation heaters,

- possibility of expanding on both sides,

- overvoltage limiters.

S - bus sectionalizer panel

| Parameters | |

| Ur | = 25 kV |

| Fr | = 50/60 Hz |

| Ud | = 50/60 kV |

| Up | = 125/145 kV |

| Ir | = 630 A |

| Ik | = do 20 kA (1s) |

| Ip | = 50 kA |

| IA | = do 22 kA |

| switch disconnector class M2, E3 | |

| earthing switch class M0, E2 | |

- meets the requirements of the PN-EN 62271-103 Switches for rated voltages above 1 kV up to and including 52 kV standard,

- the S unit as a single module expandable both to the right and to the left,

- disconnector, the construction of which is based on common moving contacts and on fixed contacts,

- switching operations arc quenching system,

- manual single or double spring drive (depending on the use of an earthing switch), which ensures intuitive and easy operation and snap-action closing and opening of the switching device,

- system display representing the state of devices and entire primary circuits,

- pressure meter - gas density indicator with a scale with two zones, indicating the rated absolute pressure of the SF6 gas - 125 kPa (0.125 MPa) at a temperature of 20°C (one per one tank),

- safety valve (one per one tank), which is opened by pressure increase caused by arcing inside the tank, directing the gases downwards, to the cable duct, eliminating the hazard to personnel.

- 24 V DC motor drive (other supply voltage on request), possibility of easy expansion at the facility,

- earthing switch of the primary circuit of the right section,

- primary circuits (before and after the disconnector) voltage indicator,

- pressure control - for operating with motor drive, telemetry,

- SEM SC 11 field controller plus local control panel, binary or Modbus communication,

- auxiliary contacts as representation of state of devices for telemetry systems,

- anti-condensation heaters,

- possibility of expanding on both sides,

- key interlock of the disconnector or earthing switch socket.

M - metering panel equipment

| Parameters | |

| Ur | = 25 kV |

| Fr | = 50/60 Hz |

| Ud | = 50/60 kV |

| Up | = 125/145 kV |

| Ir | = 630 A |

| Ik | = do 20 kA (1s) |

| Ip | = do 50 kA |

- meets the requirements of the PN-EN 62271-200 AC metal-enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV standard,

- the M unit as a single module expandable both to the right and to the left,

- a system of primary busbars enclosed in a stainless steel tank,

- a set of current transformers and voltage transformers,

- primary circuits voltage indicator,

- system display representing the state primary circuits,

- pressure meter - gas density indicator with a scale with two zones, indicating the rated absolute pressure of the SF6 gas - 125 kPa (0.125 MPa) at a temperature of 20°C (one per one tank),

- safety valve (one per one tank), which is opened by pressure increase caused by arcing inside the tank, directing the gases downwards, to the cable duct, eliminating the hazard to personnel.

- pressure control - for operating with motor drive, telemetry,

- anti-condensation heaters,

- option of connecting with side connectors or cable terminations.

TPM type MV switchgear compartment

Switching device compartment

The switching device compartment is placed in a tank made from stainless steel sheet, with SF6 gas is used as insulation, with very high dielectric strength and very good arc quenching ability. The following components were installed in the tank: primary busbars, switches and bushings. The switching device is an integrated disconnector and earthing switch, which is also opened and closed by snap-action. Each tank has a safety valve which can be opened to relieve the pressure increase caused by internal arcing. In TPM and TPM Kompact switchgear system, the valve is installed at the bottom of the tank in the cable connection compartment of one of the feeder units. Isolator bushings are equipped with capacitive voltage dividers, connected to voltage indicators located on the front panel of the switchgear cabinet. The switch disconnector itself and its drive mechanisms are exceptionally durable and reliable devices. Their design allows for 5000 operating cycles without any adjustment, maintenance, or component replacement.

Fuses compartment

Fuse links with integrated temperature limiter are installed in the switchgear fuses compartment (in special insulating tubes), in accordance with the DIN 43625 standard. The design of the fuses compartment prevents its opening before the earthing switch has been closed. Closing the switch disconnector in the transformer feeder is possible only after the fuse compartment door is closed. In the event the fuse link is blown, the striker mounted on the link trips the circuit breaker in the transformer feeder. The switch disconnector can be re-closed after replacement of the fuse links.

Drive mechanism compartment

The drive mechanism compartment contains the integrated, direct manual (motor driven) operating mechanism for switch disconnector and earthing switch or vacuum circuit breaker and disconnector with an earthing switch. The transformer feeder is moreover equipped with a stored energy release mechanism, which allows the switch disconnector to be opened after the activation of the fuse link striker, or in case a tripping coil is used. A blown fuse link is indicated on the front panel of the drive. In the switchgear cabinet operating mechanism compartment, there is a pressure gauge (calibrated to take into account state depending on temperature), which indicates the correct SF6gas pressure inside the tank. Cable voltage indicators are installed In the front side of the switchgear cabinet.

Cable compartment

In the cable compartment, cable terminations are used to connect cables from the power grid to the switchgear. Individual feeders of the cable compartments have metal partitions which separate one feeder from another.

Each cable compartment is equipped with:

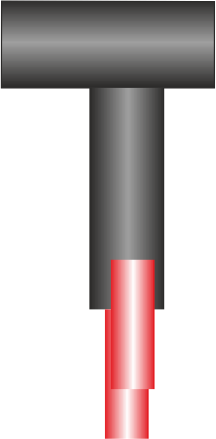

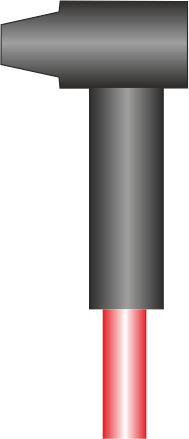

- type C insulating bushings for incoming, outgoing and transformer feeders equipped with a power circuit breaker,

- type A insulating bushings for transformer feeders equipped with MV fuses,

- cable clamps,

- earthing terminals for return cables.

Moreover each bay allows the installation of the following equipment:

- current transformers, Rogowski coils,

- voltage sensors,

- overvoltage limiters,

- combined systems with the use of deep front panels, e.g.: two terminations per phase, termination + voltage sensor, termination + overvoltage limiter, two terminations per phase + voltage sensor, two terminations per phase + overvoltage limiter, termination + overvoltage limiter + voltage sensor.

The TPM type switchgear is designed for the installation of cables with a cross-section up to 630 m2, such as:

- in plastic insulation, e.g.: YHAKXS, YHKX, XUHAKXS, XRUHKS.

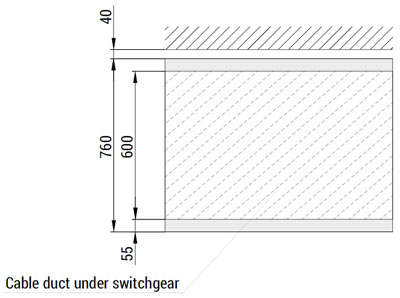

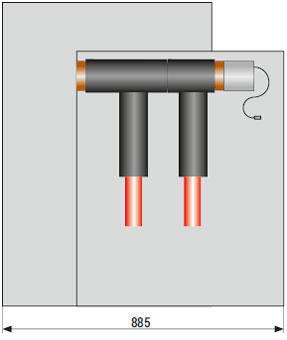

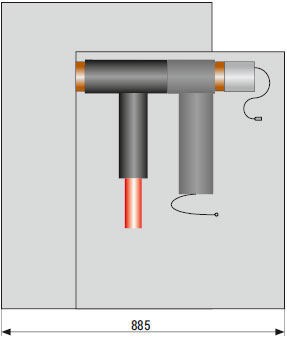

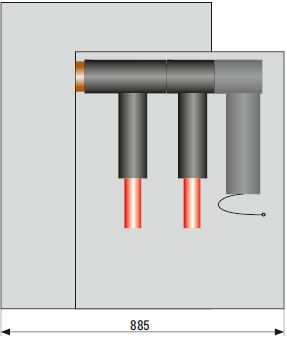

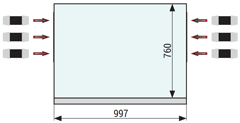

Construction method for a cable duct under the TPM type MV switchgears

Figures 1–3 present a cable duct construction proposal. The cable bending radius (which depends on its outside diameter, according to PBUE) should be taken into account when establishing the dry cables duct depth. Figure 1 shows the suggested cable duct depth. It is possible to avoid or reduce the depth of the cable duct by using a raised base or a raised floor.

| Cable cross section (mm2) | Bending radius (mm) | Duct depth K (mm) |

| 50 | 370 | 400 |

| 70 | 400 | 430 |

| 95 | 440 | 470 |

| 120 | 470 | 500 |

| 150 | 500 | 550 |

| 185 | 540 | 600 |

| 240 | 590 | 700 |

TPM switchgear cable connections

| Cable fittings - GPH EUROMOLD terminations - interface A | ||||

|

Cable type |

Cable cross-section depending on termination type |

Termination type | Cable terminal type for a given termination/cable |

Overvoltage limiter type depending on termination type |

| Single-core cables in plastic insulation with an Al and Cu phase core, with a return core of copper wires, for a voltage of 20 kV |

25-120 | K152SR (straight)1) | crimped | 156S A (possibility of connecting only with K200T) |

| 25-150 | K200SR (straight)1) | bolted | ||

| 25-150 | K158LR (angle) | crimped | ||

| 25-150 | K200LR (angle) | bolted | ||

| 1) Possibility of using in TPM Compact swiftchgear. | ||||

| Cable fittings - GPH EUROMOLD terminations - interface C | ||||

|

Cable type |

Cable cross-section depending on termination type |

Termination type | Cable terminal type for a given termination/cable |

Overvoltage limiter type depending on termination type |

| Single-core cables in plastic insulation with an Al and Cu phase core, with a return core of copper wires, for a voltage of 20 kV |

10-300 | K430TB | bolted | 300PB -10SA |

| 10-300 | K480TB | bolted | 800PB -10SA | |

| 240-630 | K484TB | bolted | 800PB -10SA | |

| 10-300 | K400TB | bolted | 400PB -10SA | |

| 185-630 | K440TB | bolted | 400PB -10SA | |

| 10-240 | K400LB | crimped and bolted | 400PB -10SA (only before the termination) |

|

| Cable fittings - CELLPACK terminations - interface A | ||||

| Cable type | Cable cross-section |

Cable termination depending on cable cross-section |

Cable terminal type for a given termination/cable |

Overvoltage limiter type depending on termination type |

| Single-core cables in plastic insulation with an Al and Cu phase core, with a return core of copper wires, for a voltage of 20 kV |

16-95 | CWS 250A 24kV 16-95 M/EGA - straight1) | (CWS C16-95)-set | NONE |

| 70-150 | CWS 250A 24kV 70-150 M/EGA - straight1) | (CWS C70-150)-set | ||

| 25-95 | CGS 250A 24kV 25-95 M/EGA - angle | (CGS C25-95)-set | ||

| 70-150 | CGS 250A 24kV 70-150 M/EGA - angle | (CGS C70-150)-set | ||

| 1) Possibility of using in TPM Compact swiftchgear. | ||||

| Cable fittings - CELLPACK terminations - interface C | ||||

| Cable type | Cable cross-section |

Cable termination depending on cable cross-section |

Cable terminal type for a given termination/cable |

Overvoltage limiter type depending on termination type |

| Single-core cables in plastic insulation with an Al and Cu phase core, with a return core of copper wires, for a voltage of 20 kV |

25-70 | CTS 630A 24kV 25-70 EGA - angle | (CTS C25-95)-set | CTKSA 18kV |

| 95-240 | CTS 630A 24kV 95-240 EGA - angle | (CTS C95-240)-set | CTKSA 24kV | |

| Cable fittings - GPH EUROMOLD terminations - interface A | ||||

| Type and manufacturer of voltage sensor (with which the terminations were tested) |

Coupling termination type, option of two cables per phase. |

Coupling termination type, option of two cables per phase + limiter |

Coupling termination type, option of two cables per phase + sensor. |

Type of insulating plug |

| KAA-VS4 (Nexans) | none | none | none | K150DR-B/G |

| KAA-VS4 (Nexans) | none | none | none | K150DR-B/G |

| KAA-VS4 (Nexans) | none | none | none | K150DR-B/G |

| KAA-VS4 (Nexans) | none | none | none | K150DR-B/G |

| Cable fittings - GPH EUROMOLD terminations - interface C | ||||

| Type and manufacturer of voltage sensor (with which the terminations were tested) |

Coupling termination type, option of two cables per phase. |

Coupling termination type, option of two cables per phase + limiter |

Coupling termination type, option of two cables per phase + sensor. |

Type of insulating plug |

| UR-65 (ITR), SMVS UW1002-1 (Zelisko), KEVA24C24(c) (ABB) | K300PB | K300PB | K300PB | K400DR-B/G |

| SMVS UW1002-3 (Zelisko), KEVA24C24(c) (ABB) | K800PB and K804PB | K800PB and K804PB | K800PB and K804PB | K400DR-B/G |

| SMVS UW1002-3 (Zelisko) | K800PB and K804PB | K800PB and K804PB | K800PB and K804PB | K400DR-B/G |

| SMVS UW1001 (Zelisko), PLUGSENS (Arteche), KEVA24C10(c) (ABB) | K400TB+K400CP or K440PB |

K400TB+K400CP or K440PB |

K400TB+K400CP or K440PB |

K400DR-B/G |

| SMVS UW1001 (Zelisko), PLUGSENS (Arteche), KEVA24C10(c) (ABB) | K400TB+K400CP or K440PB |

K400TB+K400CP or K440PB |

K400TB+K400CP or K440PB |

K400DR-B/G |

| None | K440PB (only before the termination) |

K440PB (only before the termination) |

K440PB (only before the termination) |

K400DR-B/G |

| Cable fittings - CELLPACK terminations - interface A | ||||

| Type and manufacturer of voltage sensor (operating with the terminations) |

Coupling termination type, option of two cables per phase. |

Coupling termination type, option of two cables per phase + limiter |

Coupling termination type, option of two cables per phase + sensor. |

Type of insulating plug |

| NONE | NONE | NONE | NONE | CIK 250A 24kV |

| Cable fittings - CELLPACK terminations - interface C | ||||

| Type and manufacturer of voltage sensor (operating with the terminations) |

Coupling termination type, option of two cables per phase. |

Coupling termination type, option of two cables per phase + limiter |

Coupling termination type, option of two cables per phase + sensor. |

Type of insulating plug |

| UR-65 (ITR), KEVA24C25(c) (ABB) |

CTKS 630A 24kV 25-70 EGA | on request | on request | CIK 630A 36kV |

| CTKS 630A 24kV 95-240 EGA | on request | on request | ||

| Cable fittings - TYCO ELECTRONICS terminations - interface A | |||||

| Cable type | Rated voltage Uo/U (kV) |

Cable cross-section depending on termination type |

Termination type straight / angle |

Cable terminal type for a given termination/cable |

Overvoltage limiter type depending on termination type |

| Single-core cables in plastic insulation with an Al and Cu phase core, with a return core of copper wires |

6/10 | 16-70 | RSSS 525A / RSES 525A | Bolted included | None |

| 6/10 | 95 | RSSS 525B / RSES 525B | |||

| 6/10 | 95-100 | RSSS 525C / RSES 525C | |||

| 8,7/15 | 16-50 | RSSS 525A / RSES 525A | |||

| 8,7/15 | 50-95 | RSSS 525B / RSES 525B | |||

| 8,7/15 | 70-120 | RSSS 525C / RSES 525C | |||

| 8,7/15 | 120-150 | RSSS 525D / RSES 525D | |||

| 12/20 | 16 | RSSS 525A / RSES 525A | |||

| 12/20 | 25-95 | RSSS 525B / RSES 525B | |||

| 12/20 | 70-95 | RSSS 525C / RSES 525C | |||

| 12/20 | 70-150 | RSSS 525D / RSES 525D | |||

| Cable fittings - TYCO ELECTRONICS terminations - interface C | |||||

| Cable type | Rated voltage Uo/U (kV) |

Cable cross-section depending on termination type |

Termination type straight / angle |

Cable terminal type for a given termination/cable |

Overvoltage limiter type depending on termination type |

| Single-core cables in plastic insulation with an Al and Cu phase core, with a return core of copper wires |

6/10 | 35-95 | RSTI-5851 | Bolted included | RSTI-CC-68SA**10 - LIMITERS SELECTED INDIVIDUALLY |

| 6/10 | 95-240 | RSTI-5853 | |||

| 6/10 | 185-300 | RSTI-5855 | |||

| 6/10 | 400 | RSTI-3951 | |||

| 6/10 | 500 | RSTI-3952 | |||

| 6/10 | 600 | RSTI-3953 | |||

| 8,7/15 i 12/20 | 35-70 | RSTI-5851 | |||

| 8,7/15 i 12/20 | 95-240 | RSTI-5852 | |||

| 8,7/15 i 12/20 | 185-300 | RSTI-5855 | |||

| 8,7/15 i 12/20 | 400 | RSTI-5951 | |||

| 8,7/15 i 12/20 | 500 | RSTI-5952 | |||

| 8,7/15 i 12/20 | 600 | RSTI-5953 | |||

| 8,7/15 i 12/20 | 800 | RSTI-5954 | |||

| Cable fittings - TYCO ELECTRONICS terminations - interface A | ||||

| Type and manufacturer of voltage sensor (with which the terminations were tested) |

Type of coupling termination, option of two cables per phase |

Type of coupling termination, option of two cables per phase + limiter |

Type of coupling termination, option of two cables per phase + sensor |

Type of insulating plug |

| None | None | None | None | None |

| Cable fittings - TYCO ELECTRONICS terminations - interface C | ||||

| Type and manufacturer of voltage sensor (with which the terminations were tested) |

Type of coupling termination, option of two cables per phase |

Type of coupling termination, option of two cables per phase + limiter |

Type of coupling termination, option of two cables per phase + sensor |

Type of insulating plug |

| RSTI-VS-24-BP Tyco Electronics SMVS-UW1002-0 Zelisko |

RSTI-CC-5851 | None | ||

| RSTI-CC-5853 | ||||

| RSTI-CC-5855 | ||||

| RSTI-CC-3951* | ||||

| RSTI-CC-3952* | ||||

| RSTI-CC-3953* | ||||

| RSTI-CC-5851 | ||||

| RSTI-CC-5854 | ||||

| RSTI-CC-5855 | ||||

| RSTI-CC-3951* | ||||

| RSTI-CC-3952* | ||||

| RSTI-CC-3953* | ||||

| RSTI-CC-3954* | ||||

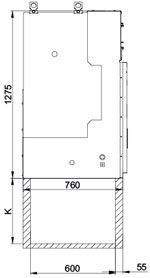

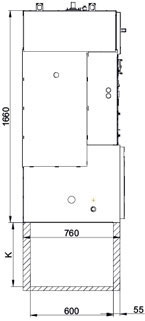

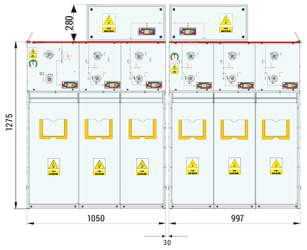

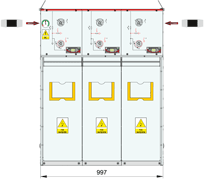

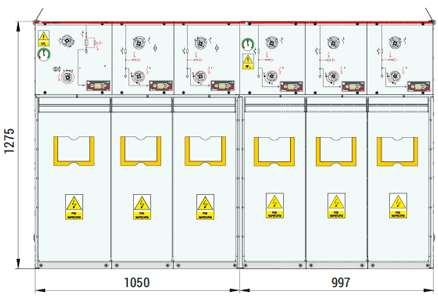

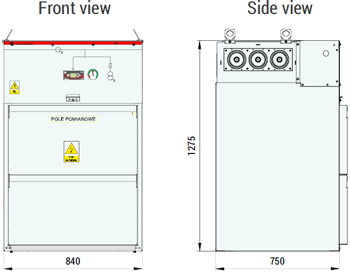

Approximate dimensions / TPM switchgear connection options

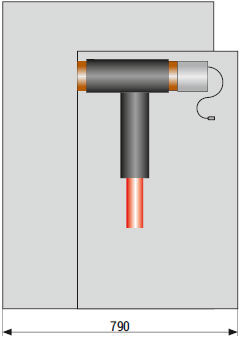

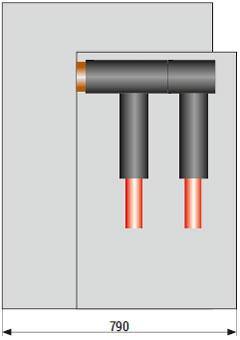

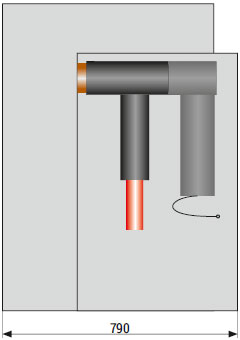

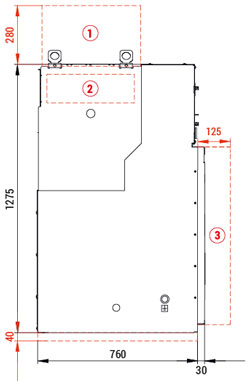

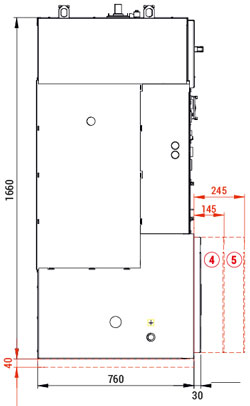

Expandable units connection method

The TPM switchgear can be expanded with additional assemblies (on the condition that this was discussed at the pricing and ordering stage). The examples of connection methods were presented on figures below. Detailed information is provided in the Switchgear Operation & Maintenance Manual.

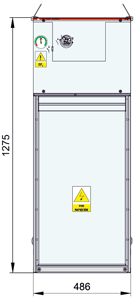

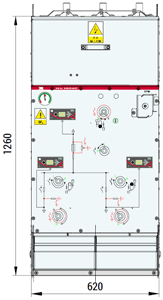

TPM switchgear side views and dimensions

1) - cover for TPM switchgear in expandable version - top connection,

2) - cover for TPM switchgear in expandable version - side connection,

3) - front panel depth of 125 mm used only in case of:

Double termination with a voltage sensor;

Termination with overvoltage limiter and voltage sensor;

K400LB termination with a 400PB overvoltage limiter.

4) - front panel depth in case of use termination with with overvoltage limiter,

5) - front panel depth in case of use termination with with overvoltage limiter and voltage sensor.

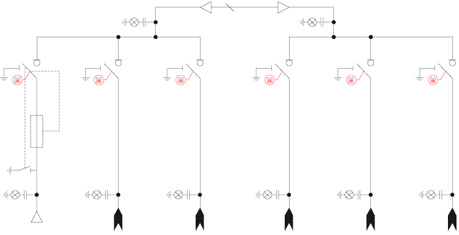

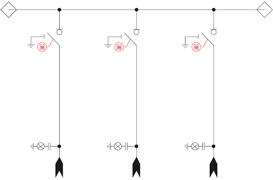

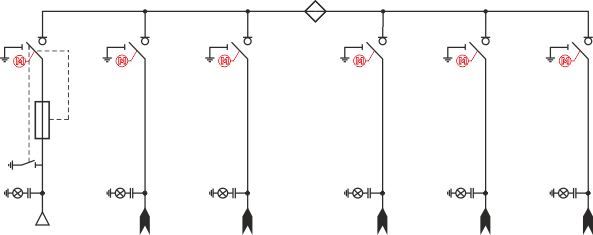

TPM - typical configurations

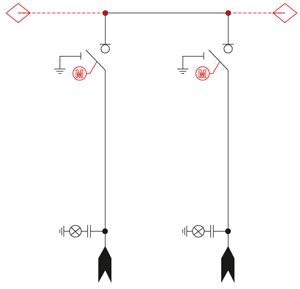

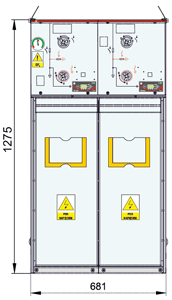

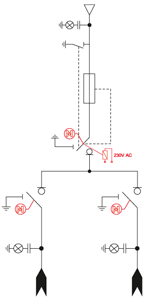

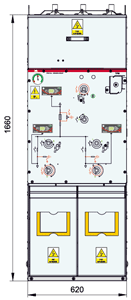

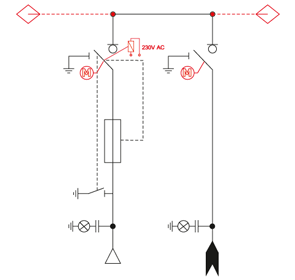

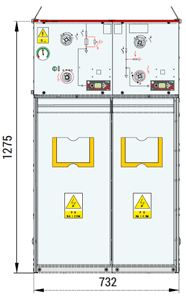

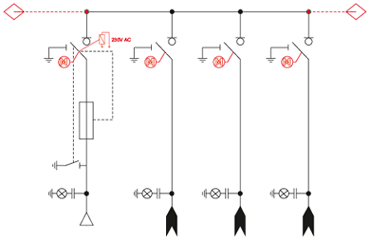

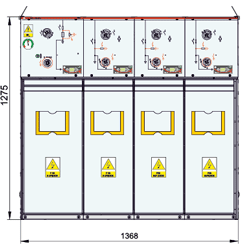

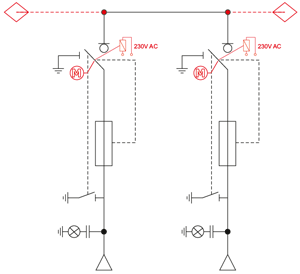

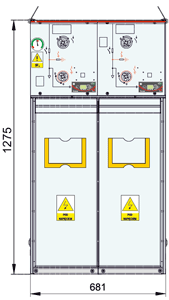

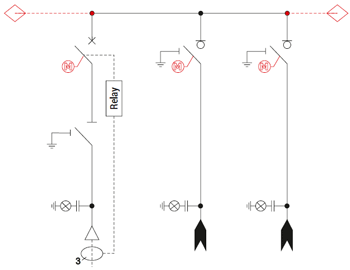

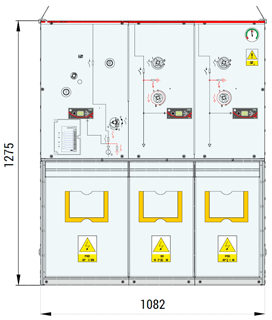

TL / LT configuration (transformer feeder, line feeder)

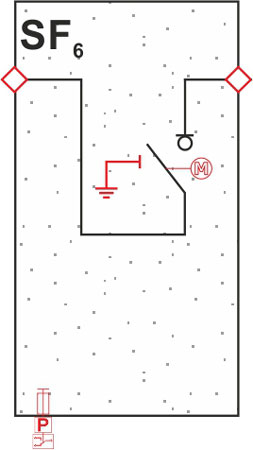

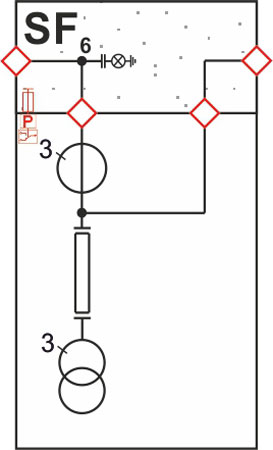

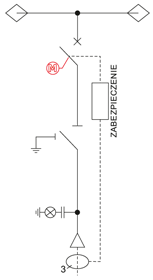

Optional equipment was marked with red on the electrical diagram.

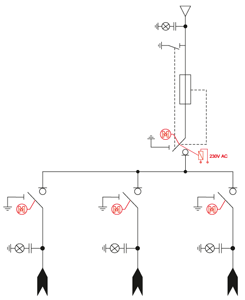

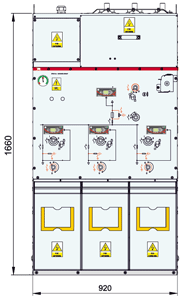

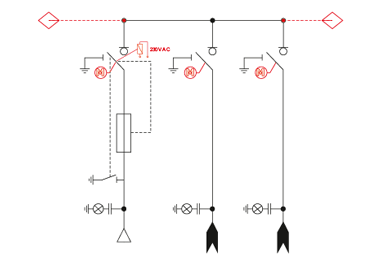

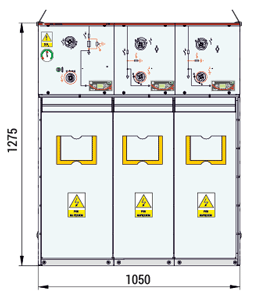

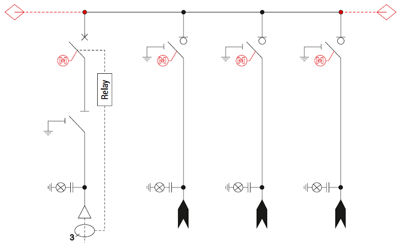

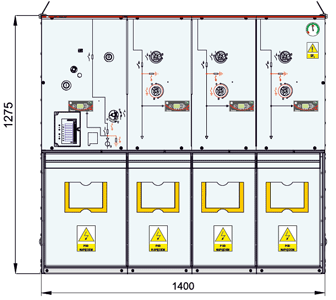

TLL / LLT configuration (transformer feeder, 2 line feeders)

Optional equipment was marked with red on the electrical diagram.

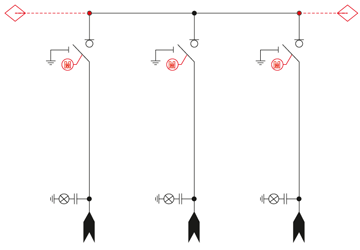

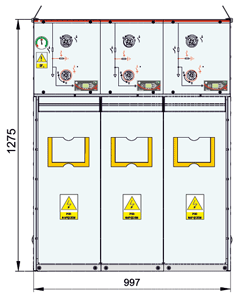

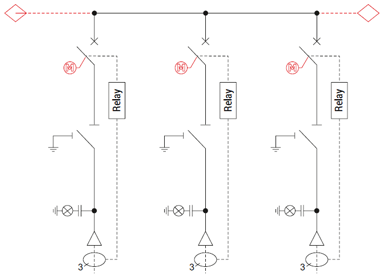

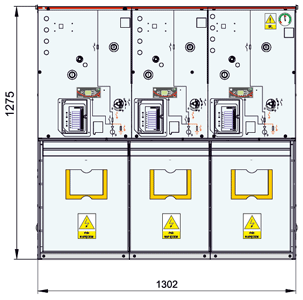

TLLL / LLLT configuration (transformer feeder, 3 line feeders)

Optional equipment was marked with red on the electrical diagram.

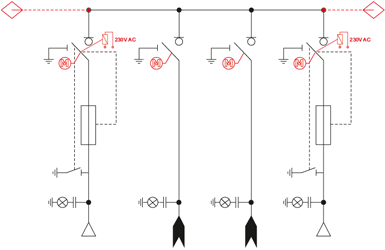

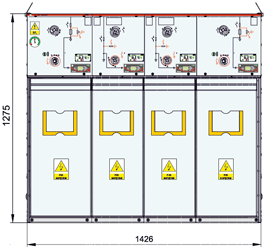

TLLT configuration (2 transformer feeders, 2 line feeders)

Optional equipment was marked with red on the electrical diagram.

TT configuration (2 transformer feeders)

Optional equipment was marked with red on the electrical diagram.

LLL configuration (3 line feeders)

Optional equipment was marked with red on the electrical diagram.

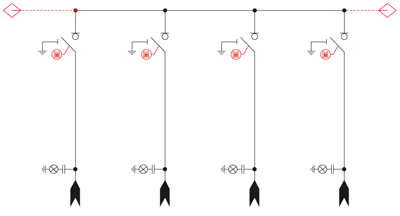

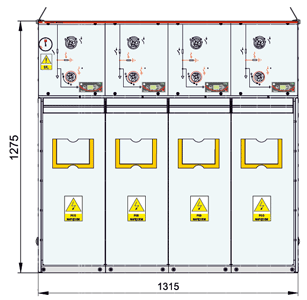

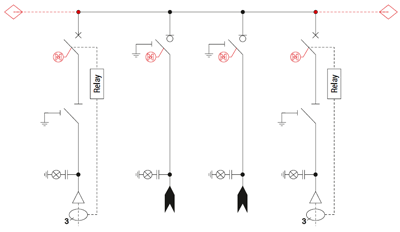

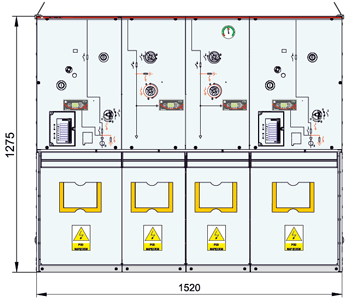

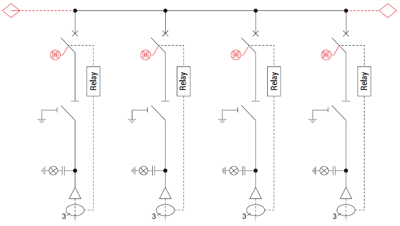

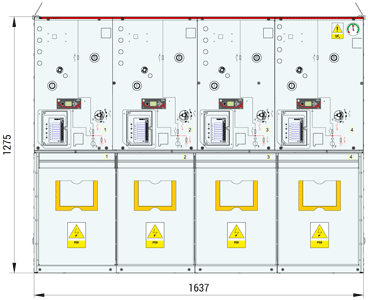

LLLL configuration (4 line feeders)

Optional equipment was marked with red on the electrical diagram.

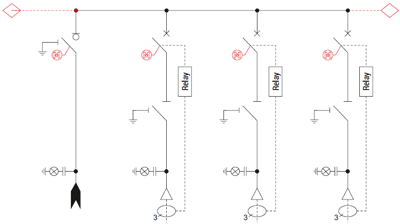

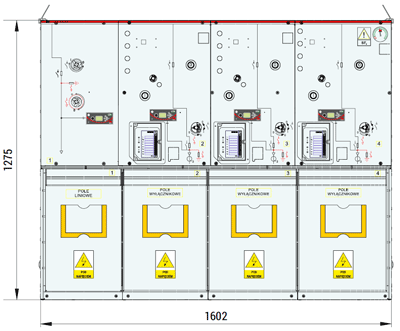

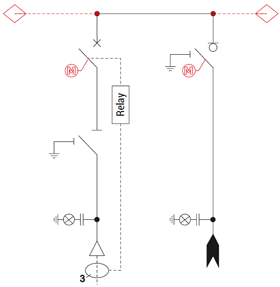

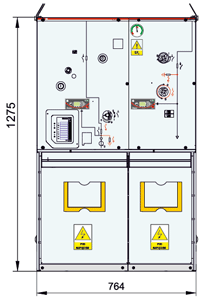

WL / LW configuration (circuit breaker feeder, line feeder)

Optional equipment was marked with red on the electrical diagram.

WLL / LLW configuration (circuit breaker feeder, 2 line feeders)

Optional equipment was marked with red on the electrical diagram.

WLLL / LLLW configuration (circuit breaker feeder, 3 line feeders)

Optional equipment was marked with red on the electrical diagram.

WLLW configuration (2 circuit breaker feeders, 2 line feeders)

Optional equipment was marked with red on the electrical diagram.

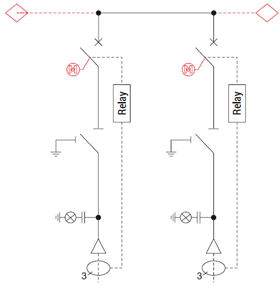

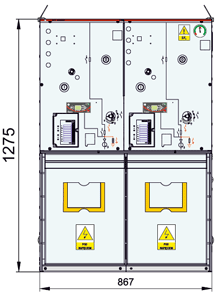

WW configuration (2 circuit breaker feeders)

Optional equipment was marked with red on the electrical diagram.

WWW configuration (3 circuit breaker feeders)

Optional equipment was marked with red on the electrical diagram.

WWWW configuration (4 circuit breaker feeders)

Optional equipment was marked with red on the electrical diagram.

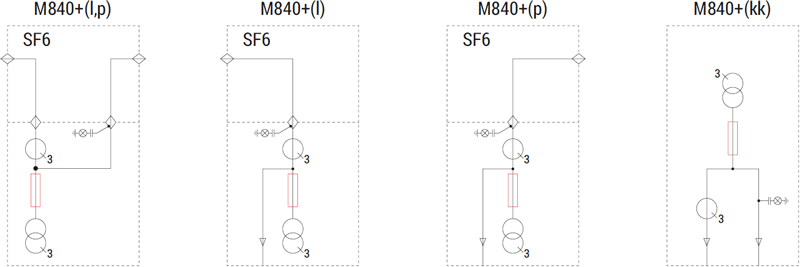

TPM - typical configurations - single units

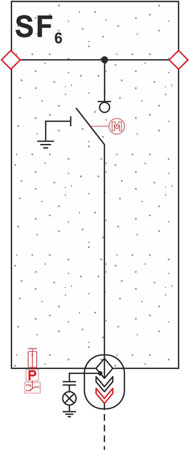

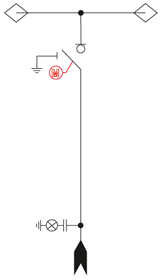

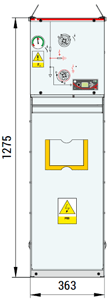

L+ (p,l) configuration (line feeder)

Optional equipment was marked with red on the electrical diagram.

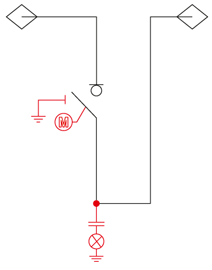

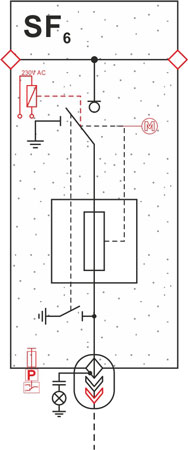

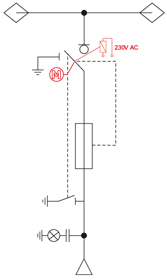

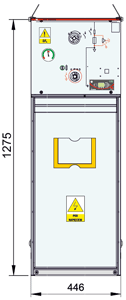

T+ (p,l) configuration (transformer feeder)

Optional equipment was marked with red on the electrical diagram.

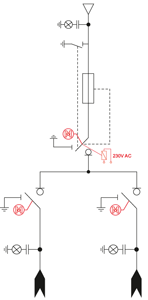

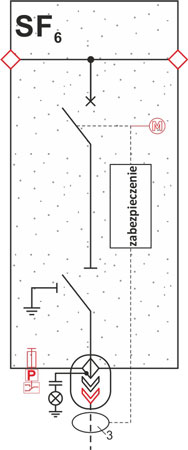

W+ (p,l) configuration (circuit breaker feeder)

Optional equipment was marked with red on the electrical diagram.

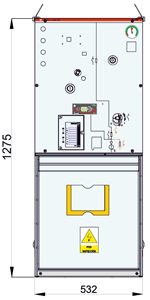

M840 metering unit

Optional equipment was marked with red on the electrical diagram.